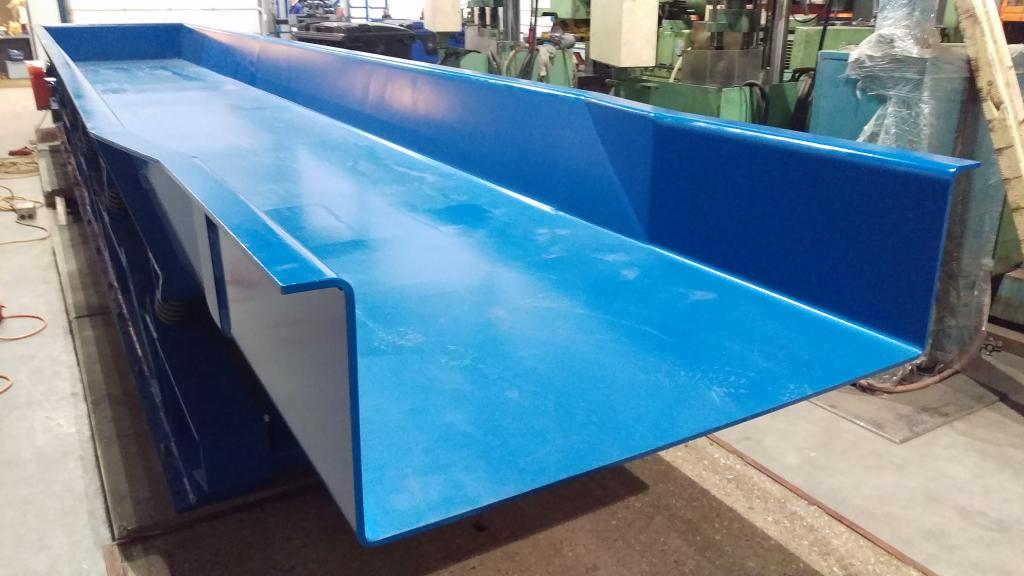

The ViPower VPLH Natural Frequency Conveyors operate at their own natural frequency, which is the frequency, in cycles per minute, of free vibration of an elastic system. For example, once set in motion, a spring mounted weight will vibrate at its natural frequency until frictional losses gradually slow it to stop. When force is periodically applied in resonance with the natural frequency of the spring and weight systems, large amplitudes of vibration can be maintained with a very small exciting force. This will provide no heavy stresses to the springs, drive-shaft and bearings, which results in a longer conveyor life, lower maintenance and power costs. Whatever the application is, Construction and demolition Waste, wood, rubber, scrap metal, domestic refuse, ViPower natural frequency conveyors handle it. The ViPower Natural Frequency Range of conveyors is available as standard, balanced, isolated or balanced & isolated. The design of a balanced feeder consists of a counterbalance weight, vibrating 180° out of phase with the vibrating trough. An Isolated conveyor design has got a feeder base beam which is several times the mass weight of the vibrating trough. The entire conveyor is supported on a structure with isolation springs. Wherever the installation of the equipment will be, ViPower can minimise vibrations up to 98%. The ViPower Natural Frequency range of conveyors are formed of laser cut tab and slot welded construction parts, which allows us to manufacture an accurate machine with short lead-times. The machines normally operate at 320 up to 470 RPM, with a stroke of 19, 22, 25 or 28 mm.