When handling demanding materials like demolition waste, scrap metal, or wood, traditional feeders can cause excessive vibration, leading to costly structural reinforcement and downtime. ViPower’s Natural Frequency Feeders (VPLH series) offer a better way.

Designed to operate at their own natural frequency, these feeders require only minimal input force to achieve powerful and controlled vibration. That means smooth operation, reduced energy consumption, and longer equipment lifespan – even in the harshest industrial environments.

The ViPower VPLH Natural Frequency Feeders operate at their own natural frequency, which is the frequency, in cycles per minute, of free vibration of an elastic system. For example, once set in motion, a spring mounted weight will vibrate at its natural frequency until frictional losses gradually slow it to stop. When force is periodically applied in resonance with the natural frequency of the spring and weight systems, large amplitudes of vibration can be maintained with a very small exciting force. This will provide no heavy stresses to the springs, drive-shaft and bearings, which results in a longer conveyor life, lower maintenance and power costs.

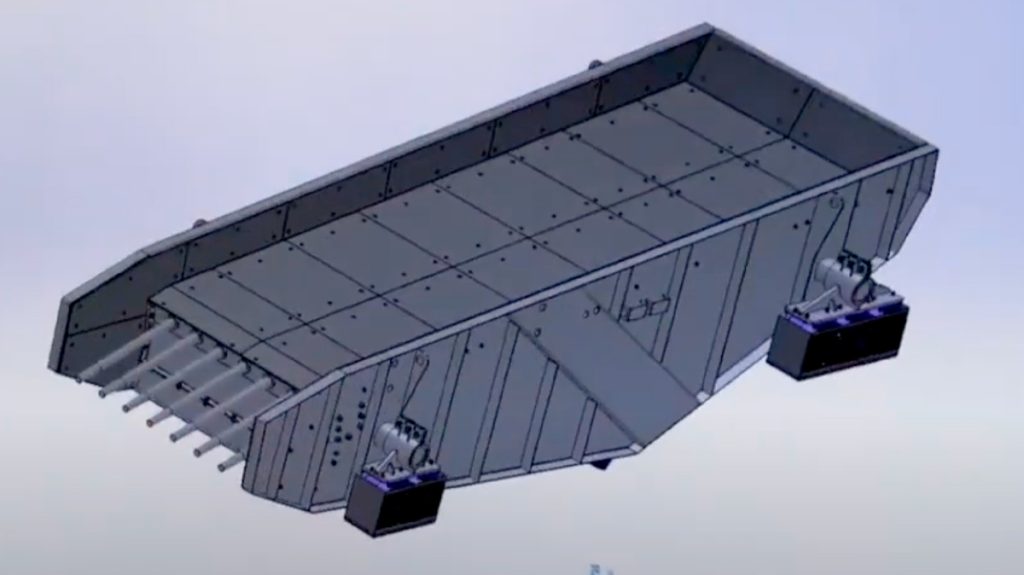

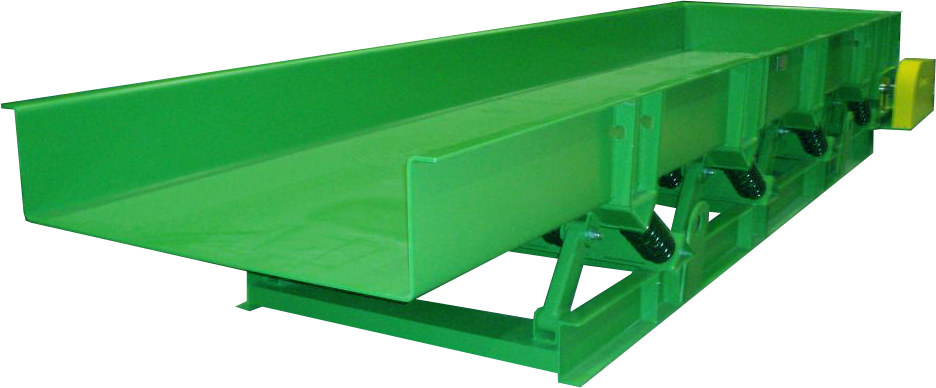

Whatever the application is, Construction and demolition Waste, wood, rubber, scrap metal, domestic refuse, ViPower natural frequency feeders handle it. The ViPower Natural Frequency Range of feeders is available as standard, balanced, isolated or balanced & isolated. The design of a balanced feeder consists of a counterbalance weight, vibrating 180° out of phase with the vibrating trough. An Isolated feeder design has got a feeder base beam which is several times the mass weight of the vibrating trough. The entire feeder is supported on a structure with isolation springs. Wherever the installation of the equipment will be, ViPower can minimise vibrations up to 98%. The ViPower Natural Frequency range of feeders are formed of laser cut tab and slot welded construction parts, which allows us to manufacture an accurate machine with short lead-times. The machines normally operate at 320 up to 470 RPM, with a stroke of 19, 22, 25 or 28 mm.

Whether you’re feeding:

Construction and demolition waste

Rubber or plastics

Scrap metals or domestic refuse

…the VPLHF range ensures continuous, reliable material flow with low operational stress. These feeders are ideal for recycling plants, bulk handling systems, and heavy-duty manufacturing.

By eliminating excessive stress on springs, shafts and bearings, our Natural Frequency Feeders drastically reduce wear and tear. The result?

Lower maintenance costs

Minimal downtime

Equipment that lasts

The machines typically run at 320 to 470 RPM, with strokes from 19 to 28 mm, tailored to your throughput and material characteristics.

All ViPower VPLHF feeders are:

Laser-cut with tab-and-slot construction for accuracy and fast delivery

Available in standard, isolated, or balanced & isolated configurations

Designed to reduce vibration transmission by up to 98% – protecting your floor, frame, or platform.

Looking for a durable, low-maintenance feeding system for your plant? Let’s talk. 👉 Get in touch or explore our full product range.

You’re not just buying a machine — you’re investing in a solution. Whether you’re upgrading an existing line or building a new one from scratch, we’ll engineer a system that fits your operation.