Whether you’re separating waste, classifying materials, or removing fines, reliable screening is critical to your process. ViPower’s Vibratory Screeners – including the SRPS (Single Rotary Powered Screener) and TRPS (Twin Rotary Powered Screener) – deliver precise, low-maintenance screening in a compact footprint.

Designed to minimize transmitted vibration, these screeners can be placed almost anywhere – with no need for heavy structural reinforcement.

The ViPower SRPS, or Single Rotary Powered Screener, range of products was designed to provide a simple, rather cheap screening solution, in a small machine. The machine has a high frequency motor (3000 RPM) which is suspended in an oscillating isolator. Therefore it will produce a small stroke and thus nearly no vibration in the support frame. This allows you to place the machine anywhere you like, without worrying about transmitted vibrations.

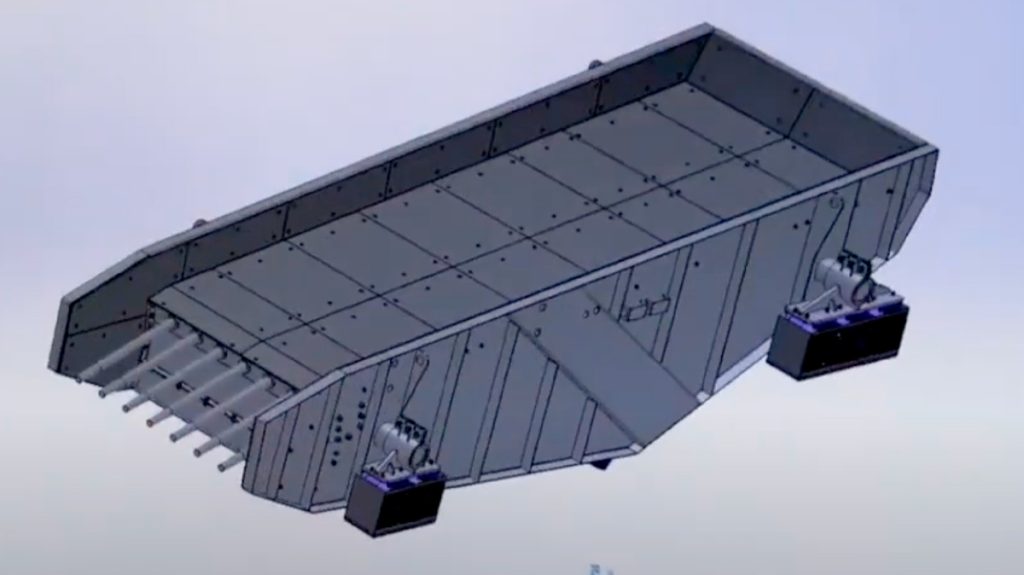

The ViPower TRPS, or Twin Rotary Powered Screener, range of products is based on two contra rotating vibratory motors, which will provide a uni-directional vibrating force. Combined with the 1000 – 1500 RPM this will provide a bigger stroke than the SRPS and thus can be used for higher capacities and tougher material. The machine is available in a single or double deck screener, grizzly screener, dewatering screener, with or without top cover, to suit your application where the product needs to separated, rather than sized. It is mounted on oscillating isolators, which will minimise vibration onto structures.

Our screening systems are used across:

Waste separation and recycling

Food and feed processing

Mining and aggregates

General industrial applications

Whether your goal is dewatering, scalping, classifying or separating, the SRPS and TRPS screeners provide the performance and adaptability your operation needs.

The SRPS model uses a high-frequency motor mounted in an oscillating isolator, producing a gentle stroke and virtually zero vibration transfer. Ideal for space-restricted or sensitive installations.

The TRPS features two contra-rotating vibratory motors, generating a stronger, unidirectional stroke. With single or double deck options, grizzly screens, dewatering screens, and optional top covers, the TRPS is suitable for higher capacities and tougher materials.

All ViPower screeners are:

Mounted on oscillating isolators to protect surrounding structures

Manufactured with laser-cut, tab-and-slot assembly for precision and strength

Designed for quick installation and minimal maintenance

Whether you need a compact solution or a heavy-duty system, ViPower screeners help you maintain product quality and process consistency.

Looking for a flexible, low-vibration screener you can depend on? 👉 Contact our team or explore the full range of screening equipment.

You’re not just buying a machine — you’re investing in a solution. Whether you’re upgrading an existing line or building a new one from scratch, we’ll engineer a system that fits your operation.