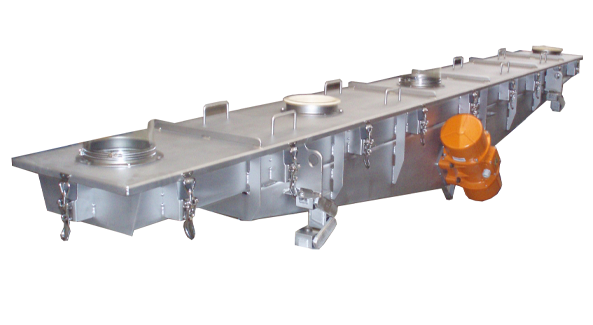

Mechanical conveyors often require belts, gears, or rollers – and lots of maintenance. ViPower’s TRPC Vibratory Conveyors offer a more reliable alternative: a robust, low-maintenance conveying system that handles a wide range of bulk materials using controlled linear vibration.

With no moving parts in contact with the product, you get clean, efficient transport that’s built to last – ideal for dusty, dirty, or abrasive environments.

From delicate goods to heavy-duty waste, the TRPC vibratory conveyors are used in:

Recycling plants

Pet food production

Bulk material handling

General processing industries

The TRPC’s linear motion ensures consistent, gentle transport while preventing product damage and buildup – even over longer distances.

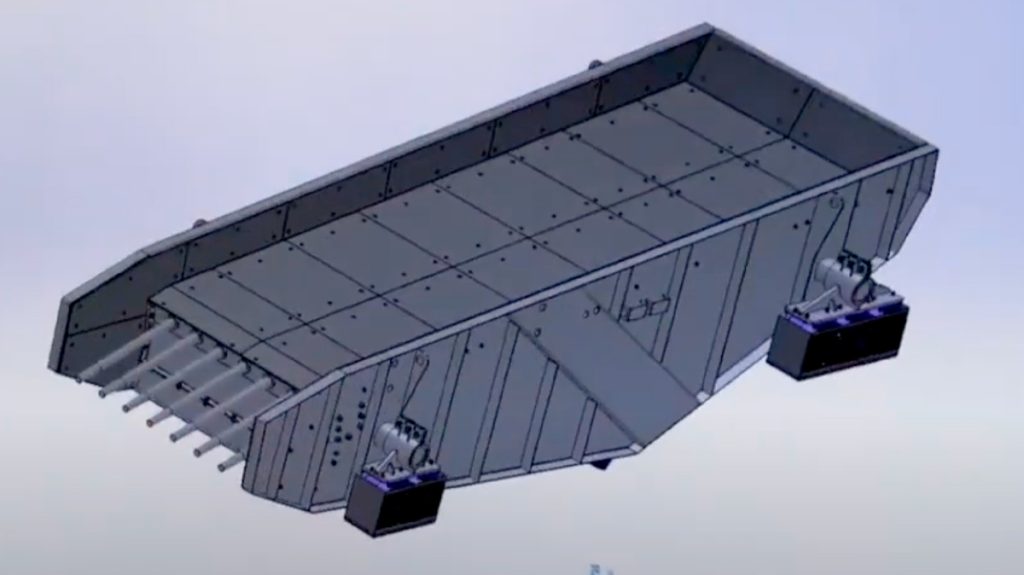

Powered by two out-of-balance motors, the TRPC delivers a strong, unidirectional stroke at up to 1500 RPM. Units are available up to 6 meters in length and 2 meters in width, with customizable options including:

Top covers and discharge chutes

Support frames and hoppers

Mild steel or stainless steel contact parts

This makes the TRPC range suitable for nearly any layout, capacity or material type.

All TRPC machines are manufactured using:

Laser-cut, tab-and-slot construction for superior fit and durability

Oscillating isolators to reduce vibration transfer to your structure

Components with over 30,000 operating hours of expected life

Optional electronic frequency inverters and phase-reversal brake units offer added control, precision and operational safety.

The ViPower range of TRPC vibratory conveyors employ with two out of balance motors and produce a linear motion. The combination of a higher stroke and up to 1500 RPM motors conveys your product to your specifications.

Employed in a wide range of industries from pet food through to recycling, the TRPC range of vibratory conveyors are highly reliable and do not need a lot of maintenance.

Units are available with dimensions up to 6 meters in length and 2 meters in width. A wide range of options is available including covers, discharge chutes and support stands. All models are available in mild steel or with stainless steel contact parts.

All machines within the ViPower TRP range come complete with a 12 month mechanical warranty. Laser profiling and “slot & tab” construction are extensively employed in our designs, ensuring optimum simplicity and durability. All major components such as motors and isolators have an expected working life in excess of 30,000 hours.

For applications where variable or metered feeds are required, the TRP range can be operated in conjunction with an electronic frequency inverter control. Also the motors can be optional supplied with a phase-reversal brake unit, to minimise out of balance when stopping.

Need a reliable, low-maintenance conveyor that performs under pressure? 👉 Contact us to discuss your requirements – or browse all ViPower conveying solutions.

You’re not just buying a machine — you’re investing in a solution. Whether you’re upgrading an existing line or building a new one from scratch, we’ll engineer a system that fits your operation.